Getting over the hump: Researchers boost high-speed laser welding for fuel cell production

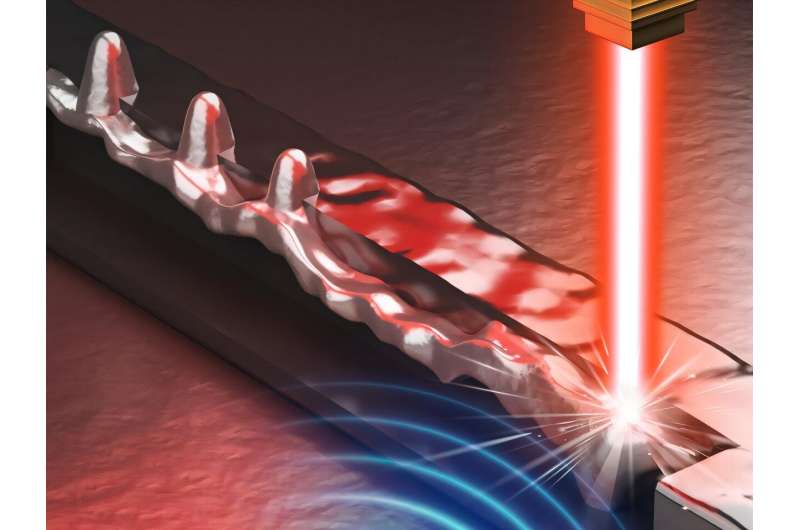

Fuel cells offer a form of clean energy across many sectors and are of particular interest in vehicles, where they produce no emissions. The production of fuel cells requires the use of a rapid laser welding process; however, welding at too high a speed results in humping, marked by surface irregularities on the weld seam.

A team led by researchers at Penn State has combined observation and analytical modeling to identify the conditions that produce humping at high laser welding speeds and to adjust the process parameters to increase weld speed without causing surface irregularities. They published their results in Nature Communications.

“We wanted to increase the laser welding speed to increase the production rate for fuel cell bipolar plates, which are an important component in fuel cells for energy generation,” said corresponding author Jingjing Li, Penn State professor of industrial and manufacturing engineering.

Bipolar plates are formed by welding two panels together. The channels that form in the bipolar plates are necessary infrastructure for energy generation in fuel cells. The production rate of bipolar plates was previously limited because welding speeds were restricted to prevent humping.

“Previously, the maximum welding speed was 20 meters of stainless steel produced per minute before humping would occur,” said first author Zen-Hao Lai, a doctoral student in the Department of Materials Science and Engineering. “Through our work, we increased that limit to 75 meters per minute.”

Lai said that a production rate of 75 meters per minutes translates to approximately 80,000 fuel cells per year, with each fuel cell consisting of two welded bipolar plates. Automotive bipolar plates typically range in size between eight-by-eight inches to 12-by-12 inches.

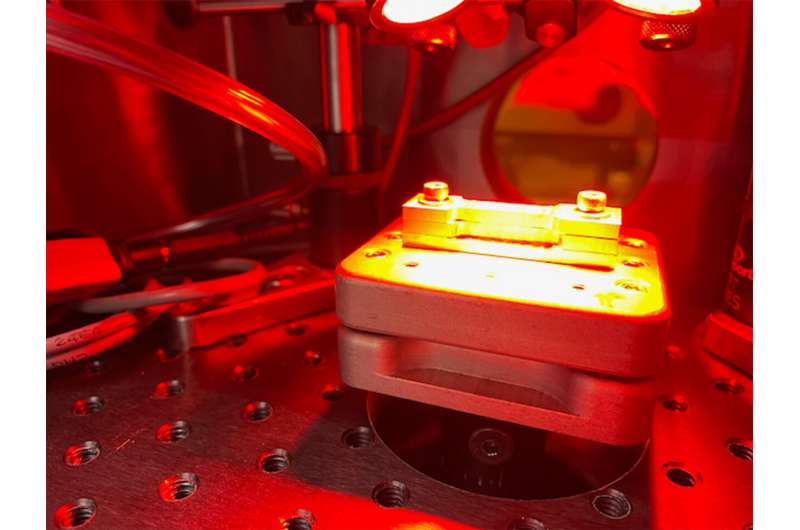

To increase the limit, the researchers first needed to gain a greater understanding of the causes of humping. Using high-speed synchrotron X-ray imaging, the team observed the process in real with unprecedented detail. They then devised a numerical simulation to correlate with the experimental observation and developed an equation to link the defects with the process parameters. By adjusting the welding conditions, the researchers could model various process parameters to create a hump-free weld even at high speeds.

Specifically, when the welding speed is too high, the materials being welded will have large molten liquid metal pools that contribute to the hump. The researchers realized that the molten pools needed to be stabilized, which they could do by applying a shielding gas or adjusting the shape of the beam that the welding laser uses. The simple adjustments, identified via their new equation, increased production rate to 75 meters of steel per minute from the 20 meters per minute rate without humps.

“By understanding the hump equation linked with the process parameters, we were able to change the parameter setting to reduce the humping,” Lai said. “The impact of the work is not only improving fundamental understanding but also resolving the technical challenge in the production process.”

The researchers said they plan to continue refining the process to achieve even higher humping-free welding speeds.

According to Li, the work challenges common notions of what industrial and manufacturing engineering is and can be.

“Something very exciting about this work for me is that it shows people that this type of engineering is not just related to hands-on manufacturing,” Li said. “This work is a good example of combining traditional manufacturing with fundamental research, and showing how fundamental knowledge can improve a process and a real-world problem.”

More information:

Zen-Hao Lai et al, Unveiling mechanisms and onset threshold of humping in high-speed laser welding, Nature Communications (2024). DOI: 10.1038/s41467-024-53888-w

Pennsylvania State University

Citation:

Getting over the hump: Researchers boost high-speed laser welding for fuel cell production (2025, January 21)

retrieved 22 January 2025

from https://techxplore.com/news/2025-01-hump-boost-high-laser-welding.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Comments are closed