Deep geothermal energy: How gas bubbles can unlock Earth’s hidden energy

Imagine a power plant fueled by heat generated deep beneath your feet, silently providing renewable energy day and night, independent of weather or sunlight. Enhanced geothermal systems (EGS) promise exactly this, tapping into Earth’s internal heat anywhere on Earth at astonishing depths of up to 15 kilometers, where temperatures exceed 400°C (752°F). But there’s a problem: How do we reliably pump geothermal fluids from these extreme environments when conventional pumps simply fail?

As an engineer focused on innovative energy technologies, I’ve spent the past several years looking for simpler, smarter ways to harness geothermal energy. Recently, our team found an intriguing answer inspired by the oil industry: gas lift technology.

Why extracting geothermal fluids is so challenging

The geothermal fluids we seek are located deep underground within human-made fractures, under conditions of extreme heat and high pressure. Current methods like electrical submersible pumps (ESPs) or line shaft pumps often break down quickly under these harsh conditions. For example, conventional ESPs fail at temperatures above 200°C, limiting our ability to tap the hottest and most valuable geothermal resources.

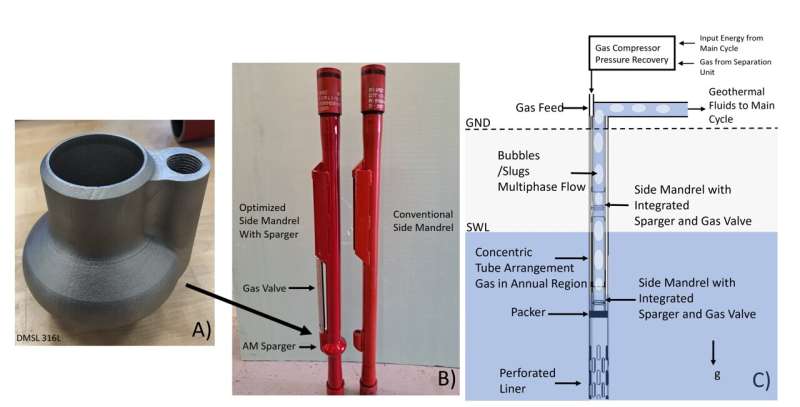

Gas lift technology, already used in more than 80% of oil wells worldwide, injects compressed gas deep underground to lift liquids to the surface. But geothermal fluid is not oil; it’s cheaper, less energy dense, and must be extracted efficiently to remain economically viable. The efficiency challenges previously overlooked in oil extraction become critical when adapting this method for geothermal use.

Could we modify gas lift technology to efficiently extract geothermal fluids from deep beneath Earth’s surface? It turns out the answer is yes—we can significantly enhance the efficiency of the gas lift process.

[embedded content]

Tiny bubbles, big impact

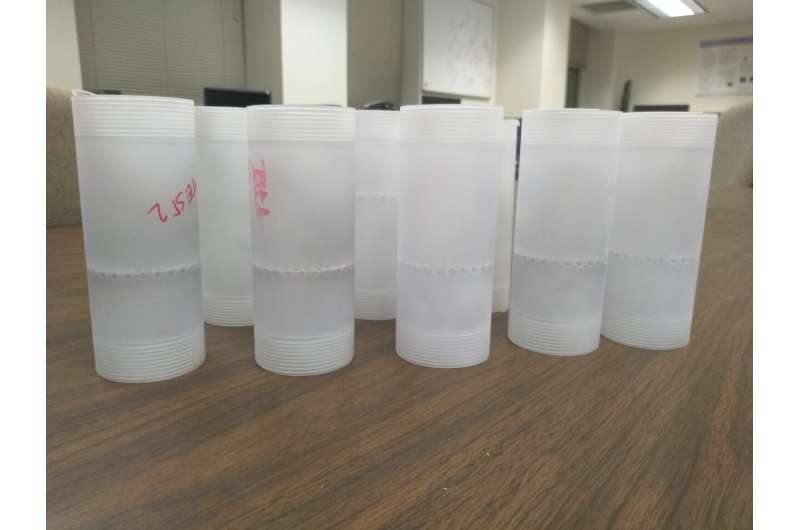

In a recent study published in Geothermal Energy, a team at West Virginia University in the Department of Mechanical, Materials & Aerospace Engineering took this question into the laboratory. We designed and 3D-printed devices called gas spargers, which have small injectors that disperse compressed gas into geothermal fluid in the form of tiny bubbles.

By conducting more than 100 scaled experiments and using advanced numerical modeling, we identified the optimal design parameters: a sparger with 51 small orifices and a carefully shaped internal channel (venturi) about 95% the diameter of the fluid pipe. Our optimized sparger created uniformly smaller bubbles, increasing fluid extraction by approximately 24% compared to traditional methods without spargers.

Why do small bubbles matter? Simply put, small, evenly distributed bubbles flow smoothly and efficiently upward, greatly improving the lifting power of the injected gas. As bubbles rise, they expand, reducing fluid density and making it easier and cheaper to pump geothermal fluid to the surface.

Robustness under harsh conditions

But efficiency alone isn’t enough. Real-world geothermal wells are harsh, mineral-rich environments that often clog equipment. To test how robust our sparger design was, we intentionally blocked many of its tiny orifices. Surprisingly, even with 62% blockage, our sparger still outperformed traditional injection methods. This resilience is vital for practical deployment.

From laboratory results to real-world potential

To verify our laboratory findings, we extrapolated our experimental results using a validated numerical model for a realistic geothermal scenario: a 4,000-foot-deep well. The optimized sparger showed a predicted 30% increase in geothermal fluid production at the same gas injection rate, suggesting a promising path forward for real-world applications.

This breakthrough could have broad implications. Enhanced geothermal systems have immense untapped potential, offering continuous, renewable, baseload power generation with minimal environmental impact. But unlocking this potential hinges on overcoming technical challenges like efficient fluid extraction from extreme depths.

Next steps: Scaling up

Currently, our team is preparing to test the optimized spargers in operational geothermal wells. Successful field demonstrations would provide definitive proof of their practical viability, opening the door to more widespread adoption.

The future we envision doesn’t rely on complex machines that frequently fail, but instead on elegant solutions inspired by nature itself. As demand for renewable energy grows, practical innovations like these could dramatically change how we tap into Earth’s abundant, hidden energy sources.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about Science X Dialog and how to participate.

More information:

Ansan Pokharel et al, Extraction of geothermal fluids from enhanced geothermal systems: optimization of a gas lift sparger, Geothermal Energy (2025). DOI: 10.1186/s40517-025-00357-2

Dr. Terence Musho is an Associate Professor in Mechanical and Aerospace Engineering at West Virginia University. His research spans advanced materials, computational modeling, and energy technologies, with a particular emphasis on developing novel systems to improve geothermal energy extraction. Dr. Musho has published extensively on energy conversion, heat transfer, and materials engineering, and leads several federally funded projects aimed at innovating sustainable energy solutions

Citation:

Deep geothermal energy: How gas bubbles can unlock Earth’s hidden energy (2025, July 30)

retrieved 30 July 2025

from https://techxplore.com/news/2025-07-deep-geothermal-energy-gas-earth.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Comments are closed