World’s first kilowatt-scale elastocaloric green cooling device developed

Researchers at the Hong Kong University of Science and Technology (HKUST) have developed the world’s first kilowatt-scale elastocaloric cooling device. The device can stabilize indoor temperatures at a comfortable 21°C–22°C in just 15 minutes, even when outdoor temperatures reach between 30°C and 31°C, marking a significant breakthrough toward the commercial application of elastocaloric solid-state cooling technology.

The research findings have been published in the journal Nature, offering a promising solution to combat climate change and accelerate the low-carbon transformation of the global cooling industry.

As global warming intensifies, the demand for air conditioning and cooling has been growing, with cooling already accounting for 20% of global electricity consumption. Mainstream vapor compression cooling technology relies on refrigerants with high global warming potential (GWP).

As an eco-friendly alternative, solid-state cooling technology based on the elastocaloric effect of shape memory alloys (SMAs) has drawn substantial focus from both academia and industry due to its zero greenhouse gas emissions and high energy efficiency potential.

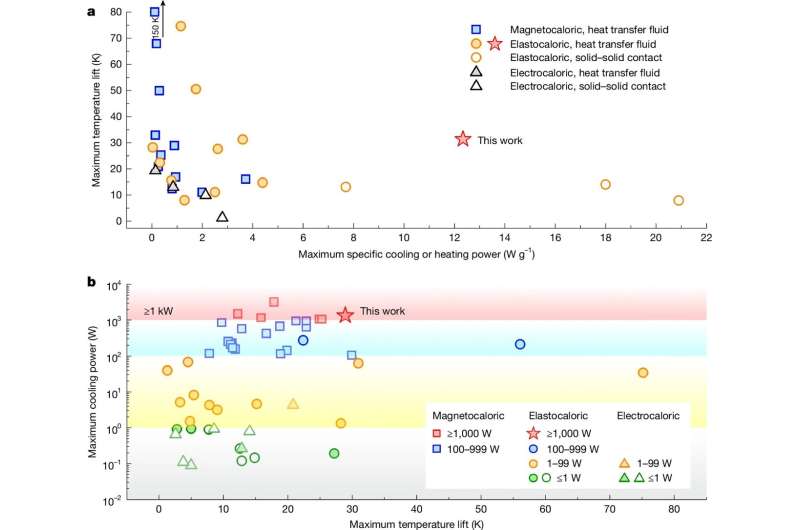

However, the maximum cooling power of previous elastocaloric cooling devices was around 260 watts, which could not meet the kilowatt-scale requirement for commercial air conditioning. The HKUST research team, led by Prof. Sun Qingping and Prof. Yao Shuhuai, both professors from the Department of Mechanical and Aerospace Engineering (MAE), identified that this bottleneck stems from two core issues: (1) the difficulty in balancing the specific cooling power (SCP) of the refrigerant with the total active mass; and (2) insufficient heat transfer efficiency during high-frequency operation.

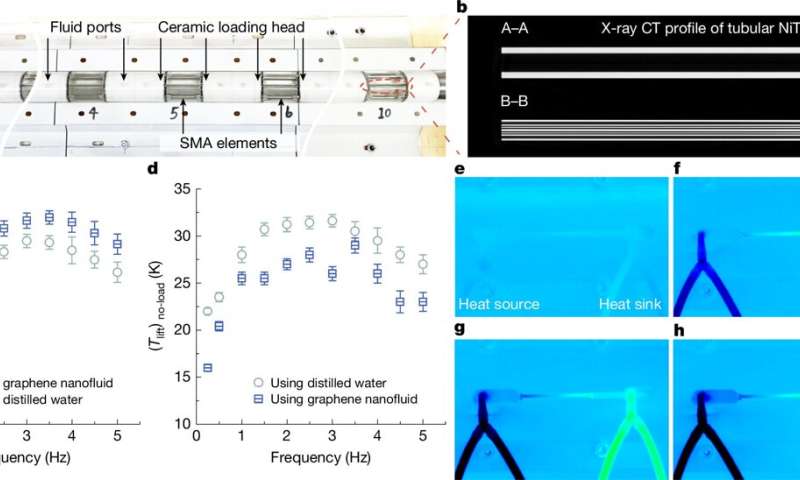

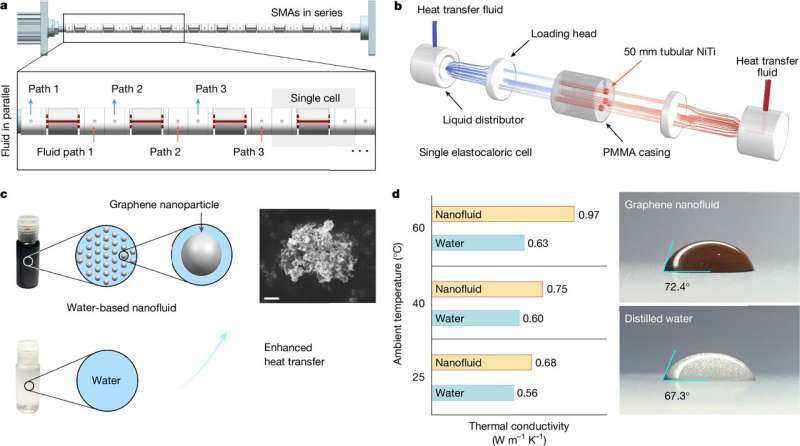

To overcome these limitations, the research team proposed an “SMAs in series—fluid in parallel” multi-cell architecture design. This architecture serially connects 10 elastocaloric cooling units along the direction of force application, with each unit containing four thin-walled nickel-titanium alloy tubes, totaling a mass of only 104.4 grams.

The nickel-titanium tubes feature a high surface area-to-volume ratio of 7.51 mm-1 that significantly improves heat exchange efficiency. Meanwhile, the parallel fluid channel design keeps system pressure below 1.5 bar, ensuring stable high-frequency operation.

Another key innovation is replacing traditional distilled water with graphene nanofluid, a cutting-edge heat transfer medium with exceptional thermal conductivity. Experiments showed that graphene nanofluid, at just 2 grams per liter concentration, conducts heat 50% more efficiently than distilled water.

The diameter of its nanoparticles (0.8 micrometers) is much smaller than the width of the fluid channels (150–500 micrometers), avoiding blockage risks. X-ray tomography confirmed that the nickel-titanium tubes maintained uniform compressive deformation under a stress of 950 megapascals without buckling failure.

-

Assembly and operation of the elastocaloric cooling device. Credit: Nature (2025). DOI: 10.1038/s41586-024-08549-9

-

Application of our kilowatt-scale elastocaloric cooling device. Credit: Nature (2025). DOI: 10.1038/s41586-024-08549-9

At a high frequency of 3.5 Hz, the device achieved a specific cooling power of 12.3 W/g and a total cooling power of 1,284 watts (under zero temperature lift conditions), demonstrating its practical viability in real-world conditions.

In practical application tests, the device successfully cooled a 2.7 m3 model house in a summer outdoor environment with temperatures between 30℃ and 31℃, stabilizing the indoor temperature at a comfortable 21℃–22 ℃ in 15 minutes.

Compared with existing solid-state cooling technologies, this pioneering device leads in terms of cooling power and temperature lift performance. Its SCP value (12.3 W/g) nearly triples the previous record of liquid heat transfer elastocaloric devices (4.4 W/g), and it has for the first time broken through the kilowatt-scale cooling threshold.

Prof. Sun Qingping said, “This achievement demonstrates the potential for the large-scale application of elastocaloric cooling technology. We are working with the industry to drive its commercialization.

“As global regulations on hydrofluorocarbons (HFCs) tighten, this zero-emission, energy-efficient cooling technology is poised to reshape the air conditioning industry and provide a key technical solution for carbon neutrality. Consumers will also benefit from lower energy bills while the technological advancements enable more compact cooling devices that save valuable indoor space.”

Prof. Yao Shuhuai said, “In the future, the system’s cooling performance can be further improved by developing new elastocaloric materials and optimizing the rotary drive architecture. These improvements can help achieve larger cooling powers, meaning indoor environments can be cooled down in significantly less time.”

This innovation has come as another major breakthrough by the research team in less than a year. It builds on their previous success with a multi-material elastocaloric device that sets a record of 75 K temperature life, as published in Nature Energy in 2024.

More information:

Guoan Zhou et al, Achieving kilowatt-scale elastocaloric cooling by a multi-cell architecture, Nature (2025). DOI: 10.1038/s41586-024-08549-9

Hong Kong University of Science and Technology

Citation:

World’s first kilowatt-scale elastocaloric green cooling device developed (2025, March 11)

retrieved 12 March 2025

from https://techxplore.com/news/2025-03-world-kilowatt-scale-elastocaloric-green.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Comments are closed